Silver plated, tinned and bare stranded products up to 16 mm² cross section are produced in our advanced technology stranding lines.

Stranded products are produced by compressing and twisting thin wires of a certain number and diameter. A stranded wire of the same cross-section is more flexible and easier to handle than a solid conductor. To achieve this greater flexibility, the diameter of the wires is thinned and wires of smaller diameter are joined together. Stranded wires are named according to their geometrical structure, strand length and twisting direction, which are determined by their intended use.

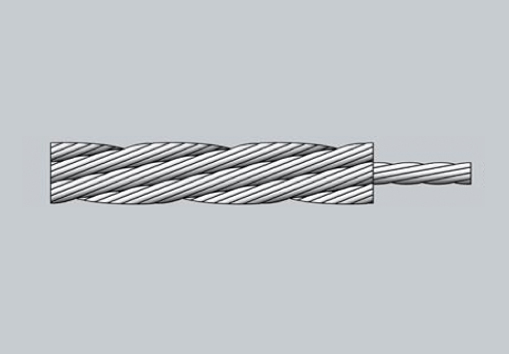

Normal stranded products are obtained by twisting one or more stranded bundles with a certain pitch length. There is no geometric arrangement of the wires in the conductors.

A rougher surface is obtained compared to concentric stranded products.

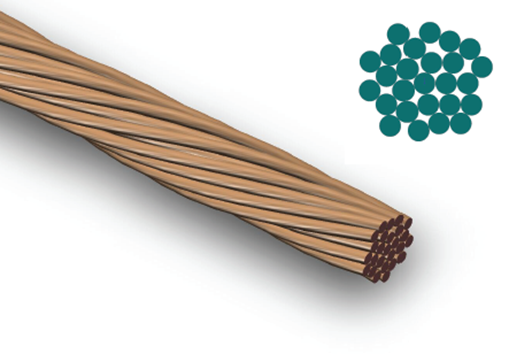

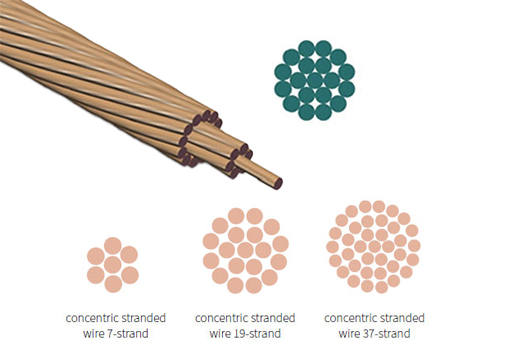

Concentric stranding is the most preferred form of stranding in cable conductors. In this twist, there is a wire in the center and one or more layers surrounding this wire.

The number of wires of each layer is 6 more than the previous layer.

It is a mixture of normal twist and concentric twist. They can be produced in two different ways depending on whether the lower layers are normal twisted or concentric twisted.

There are three types of rope twists according to their structure.