What are Bunched Copper Wires?

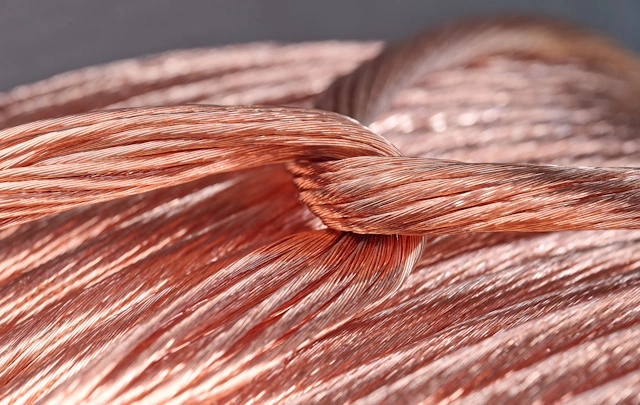

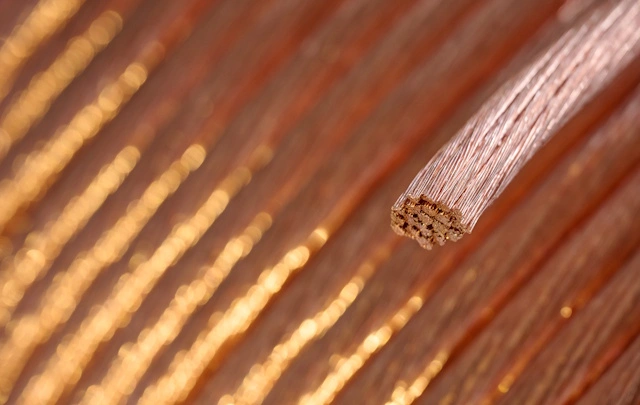

Bunched copper wires are a type of conductor formed by bundling multiple thin wires together and winding them in a specific arrangement.

These wires are combined to provide greater flexibility and durability and are commonly used in various fields such as electrical transmission, data transfer, and mechanical force applications. The twisting process strengthens the structural integrity of the wire, making it more resistant to vibrations, stress, and environmental conditions.

Unlike a single continuous conductor, the flexibility of bunched copper wires provides significant advantages, especially in systems with moving parts. They are preferred in both electrical transmission and applications requiring mechanical durability. For example, copper bunched copper wires are widely used in electrical cables due to its high electrical conductivity. The high conductivity of copper, combined with the bunched copper wires structure of the wires, offers a durable and reliable solution.

What Are the Types of Bunched Copper Wires?

Normal Twisting

Normal twisting is the most basic form among bunched copper wires types. In this technique, wire bundles are wound around an axis at equal intervals in a simple arrangement.

Normal bunched copper wires provide a balanced structure between flexibility and strength. They are generally preferred for low-cost solutions and everyday applications because the manufacturing process is simpler than other twisting types. Normal twisting is commonly used in electrical cables, small mechanical parts, and various fasteners.

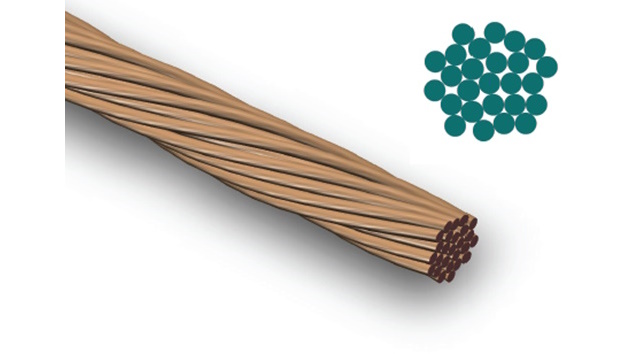

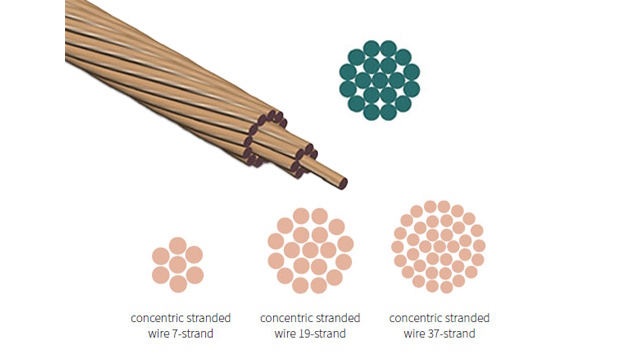

Concentric Twisting

Concentric twisting is achieved by distributing multiple wires around a central wire, layering them at specific intervals and compression rates.

This structure is more complex than normal twisting and provides a smoother wire surface. Concentric bunched copper wires are especially preferred in electrical transmission and precise data transfer. In applications such as high-voltage lines and electronic device cables, the smooth structure provided by this type of twisting makes the transmission more efficient and reliable.

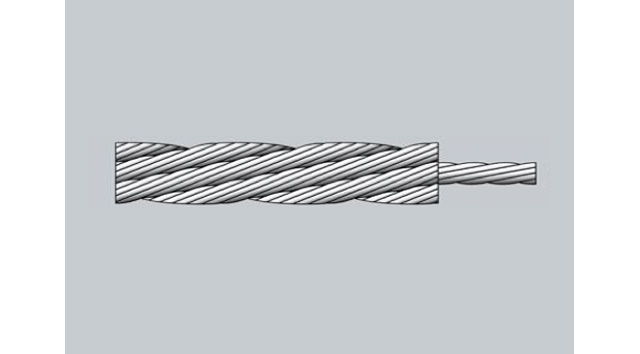

Rope Twisting

Rope twisting is created by winding thin wires in bundles or previously bunched thin wires in a rope form at specific intervals.

This type offers more flexibility compared to other twisting types and provides durability in applications that carry heavy loads. Rope bunched copper wires are commonly used in construction, marine, and mining fields, where challenging working conditions exist. Due to their flexible structure, they perform seamlessly in systems that experience continuous movement or operate under high stress.

What Are the Areas of Use for Bunched Copper Wires?

Bunched copper wires are used in many fields requiring flexibility and durability. They are preferred in a wide range of applications, from electrical and telecommunications sectors to low-current carriers and high-voltage lines to data cables. Their bunched structure facilitates electrical transmission while providing resistance to vibrations and mechanical stresses. These features make bunched copper wires ideal for use in electric motors, generators, and energy transmission lines.

Additionally, bunched copper wires are also widely used in sectors such as automotive and aerospace, where moving parts and flexibility are required. Especially in flexible cable systems, they are preferred in vehicle wiring systems due to their vibration resistance. Furthermore, the durability of bunched copper wires increases their applicability in outdoor conditions.

What Are the Properties of Bunched Copper Wires?

One of the most important properties of bunched copper wires are their combination of flexibility and durability. The twisting together of multiple wires increases the mechanical strength of the wire while providing greater flexibility. These wires resist tensile forces and vibrations. The durability of bunched copper wires are particularly why they are preferred in high-voltage applications.

Another significant characteristic of bunched copper wires are electrical conductivity. Copper bunched copper wires efficiently conduct electrical current due to their high conductivity. The bunched structure minimizes electrical losses and enhances the reliability of transmission lines. Additionally, both coated and uncoated options provide long-term durability even in harsh environmental conditions.

How Is Bunched Copper Wires Produced?

The production process of bunched copper wires essentially begins with the winding of multiple thin wires in a specific arrangement. First, the wires to be used (such as copper or aluminum) are produced in the required size and thickness. Then, these wires undergo a twisting process using specialized machines. The twisting process can be carried out in different ways, depending on the type of wire and its application. Techniques such as normal twisting, concentric twisting, or rope twisting are employed in this process.

Once the twisting process is completed, the wires undergo final quality control checks. Especially for wires to be used in electrical transmission, conductivity tests are conducted. Additionally, some wires are subjected to coating processes to enhance environmental durability. The procedures carried out throughout the production process are designed to maximize both the mechanical and electrical performance of the wire.

What Are the Advantages of Bunched Copper Wires

One of the main advantages of bunched copper wires are their combination of flexibility and durability. Thanks to the twisting process, the wires provide long-lasting durability even in moving systems. This leads to the preference for bunched copper wires in areas such as electric motors, generators, and automotive applications, which are particularly exposed to vibrations. The mechanical strength of these wires ensures reliable performance even over prolonged use.

Another advantage is their electrical conductivity. Copper bunched copper wires minimize energy losses due to their high conductivity characteristics. This feature is particularly advantageous in long-distance energy transmission lines or sensitive electronic devices. Additionally, the ability to coat bunched copper wires provides extra protection against corrosion and wear, contributing to their longevity even in challenging environmental conditions.

What Is the Importance of Bunched Copper Wires?

Bunched copper wires hold significant importance in modern industry and technology. By combining features such as flexibility, durability, and conductivity, these wires play a critical role in energy transmission and data transfer. Used in many areas, from electric motors to generators and telecommunications networks, bunched copper wires provide high performance and reliability.

The importance of these wires becomes even more apparent in systems with moving parts. Thanks to their flexible structure, bunched copper wires ensure long-lasting performance even in continuously moving or vibrating environments. Therefore, bunched copper wires are indispensable in sectors such as automotive, aerospace, construction, and electricity generation.