What is Wire Rod?

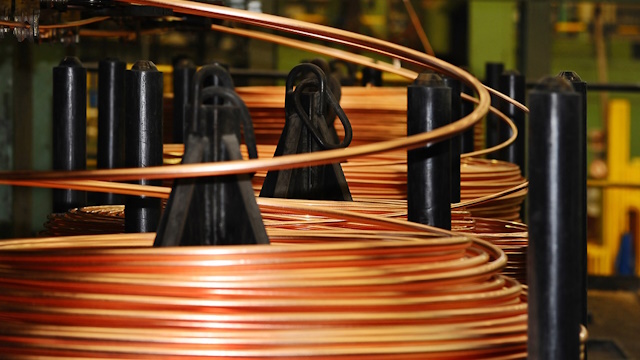

Wire rod is produced by melting high-purity copper cathodes and processing them through various methods into coils with standard diameters ranging from 8 mm to 20 mm.

How is Wire Rod Obtained and What Are Its Types?

Wire rod is obtained from hot-melted copper. The production process begins with the melting of copper at high temperatures. The molten copper is then processed to achieve a specific thickness and diameter. Afterward, a cooling process is applied, and the material is shaped into a round or oval cross-section. During this process, the wire rod becomes suitable for wire drawing or other shaping processes.

Wire rods are divided into two types: OXYGEN-FREE and OXYGEN-CONTAINING.

OXYGEN-FREE WIRE RODS: High-purity copper cathodes are melted in an induction furnace in a protective atmospheric environment at the UPCAST continuous casting facility. Using the UPCAST continuous casting method, they are produced as wire rods with standard diameters of 8-20 mm and then coiled.

OXYGEN-CONTAINING WIRE RODS: Electrolytic copper cathodes are melted in a shaft furnace in an oxygen-controlled atmospheric environment and then transported to a holding furnace through runners. From there, they are sent to a Southwire casting machine. Continuous casting is performed in bar form with an automatic metal feeding system. The resulting bar is subjected to a hot rolling process using a synchronized system, transforming it into wire rods with diameters of 8 mm to 16 mm. The wire rods are then polished and cooled on a stripping line before being presented in coils.

Where is Wire Rod Used?

Wire rod, when processed into thin wire form, is widely used in various industrial areas such as electrical transmission lines, electrical and electronic applications, the telecommunications sector, internal connections of electrical devices and appliances, the automotive industry, as well as in aerospace and aviation.

What Are the Properties of Wire Rod?

| ETP WIRE RODS | OF WIRE RODS | |

| Nominal diameters | 8,0-11,0-16,0 mm(5/16’’,7/16’’,5/8’’) | 8,0-12,5-20,0 mm |

| Diameter tolerance | ±0,38 mm (±0,015’’) | ±0,38 mm (±0,015’’) |

| Oxygen content | 180-300 ppm | Max:5 ppm |

| Conductivity | 58,5 m/ohm mm2 | 58,8 m/ohm mm2 |

| Elongation % | Min. %35 | Min. %35 |